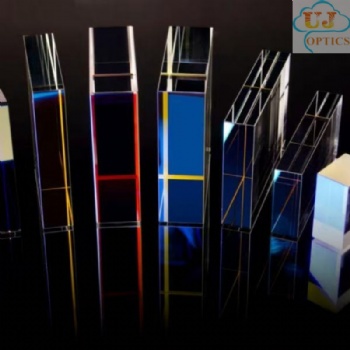

Material selection: BK7 glass has good transparency and chemical stability, and is a commonly used substrate for light guide blocks. In some scenarios, it can be used in combination with K9 glass or sapphire materials to meet different needs (such as sapphire can be selected when high wear resistance is required).

Processing technology: Supports precision machining such as six sided polishing to ensure efficient light transmission, suitable for structures such as light guide columns and blocks, commonly used in optical systems in beauty instruments.

Typical application areas of BK7 light guide block

Medical and beauty equipment

In medical imaging equipment such as X-ray machines and endoscopes, BK7 light guide blocks are used for optical path conduction to ensure image clarity; Beauty equipment, such as laser skin rejuvenation devices, utilize their high transmittance characteristics to transmit energy and improve treatment accuracy.

Precision instrument manufacturing

Optical microscopes, laser measuring equipment, etc. require light guide blocks to achieve optical path turning and focusing. The low dispersion characteristics of BK7 material can reduce light deviation and ensure measurement accuracy.

Consumer Electronics and Industrial Sector

BK7 light guide blocks are used in some high-end sensors and light guide column components, and their weather resistance and stability can meet the long-term use requirements under complex working conditions.

Market and selection points of BK7 light guide block

Market supply situation

At present, BK7 light guide blocks on the market are mostly customized products, and mainstream suppliers include optical component manufacturers and e-commerce platforms, which can provide services such as six sided polishing and size customization. In terms of material selection, BK7 and K9 glass are often recommended in parallel, with similar optical properties, but BK7 is slightly superior in heat resistance and mechanical strength.

Purchase precautions

Optical parameters: It is necessary to clarify the transmittance (usually requiring>90%), dimensional tolerances, and surface smoothness to avoid affecting the optical path efficiency;

Application scenario matching: High end fields such as healthcare and aerospace require the selection of products that meet industry standards, while industrial scenarios can balance performance requirements based on cost budgets;

Supplier qualification: Priority should be given to manufacturers with ISO certification or cooperation with well-known enterprises to ensure material purity and processing accuracy.

Industry development trend of BK7 light guide block

With the development of optical technology towards miniaturization and high precision, BK7 light guide blocks are upgrading towards integrated design (such as combining with prisms and lenses) and special coating treatments (such as anti reflective films and anti reflective films). At the same time, domestic enterprises are gradually enhancing their independent supply capability of BK7 materials through technological research and policy support, promoting cost optimization and performance breakthroughs in components such as light guide blocks.

Precautions

Cleaning and maintenance: Use a soft cleaning cloth and specialized cleaning agent to clean and avoid scratching the surface.

Storage environment: Store in a dry, well ventilated environment to prevent moisture and mold.

Usage: During use, avoid severe vibration and collision to avoid affecting its optical performance.

Please tell us the material, size, laser power, application before quote.